cnc electrical discharge machining Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with . See more Production of high-precision and complex single and series parts. Assembly of modules and complete systems. Our expertise for your mechanical engineering projects. Benefit from our modern machinery. We’re here to answer your question.

0 · wire electrical discharge machining process

1 · wire electrical discharge machine

2 · wire cut electrical discharge machining

3 · what is electrical discharge machining

4 · types of electric discharge machining

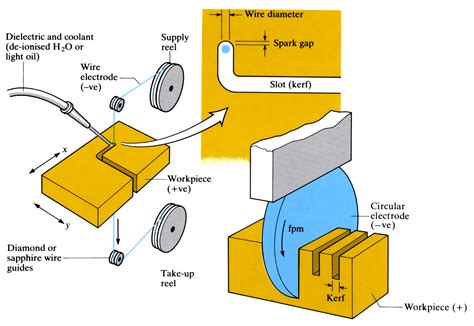

5 · electron discharge machining diagram

6 · electrical discharge machining cost

7 · diagram of electrical discharge machining

Experience top-notch metal fabrication from a leading manufacturer. Explore our state-of-the-art equipment, diverse services, and custom finishing options. Full Service Metal Fabrication | Punching, Laser Cutting, Forming Stamping, Welding, & Finishing | ISO 9001:2015 Certified

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring . See more

The erosive effect of electrical discharges was first noted in 1770 by English physicist Joseph Priestley.Die-sink EDMTwo Soviet . See moreThe first serious attempt at providing a physical explanation of the material removal during electric discharge machining is perhaps that of Van Dijck. Van Dijck presented a thermal model together with a computational simulation to explain the . See morePrototype productionThe EDM process is most widely used by the mold-making, tool, and die industries, but is becoming a . See more

Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with . See moreDifficulties have been encountered in the definition of the technological parameters that drive the process.Two broad . See moreSinker EDMSinker EDM, also called ram EDM, cavity type EDM or volume EDM, consists of an electrode and workpiece submerged in an insulating liquid such as, more typically, oil or, less frequently, other dielectric fluids. The electrode and . See moreEDM is often compared to electrochemical machining. Advantages of EDM include:• Ability to machine complex shapes that would otherwise be difficult to produce with conventional cutting . See more

Electrical Discharge Machining (EDM) is a precision manufacturing process utilizing controlled electrical sparks to remove material from conductive workpieces. The process operates .Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1]Electrical Discharge Machining (EDM) is a precision manufacturing process utilizing controlled electrical sparks to remove material from conductive workpieces. The process operates through electrical discharges between an electrode and workpiece, both submerged in a dielectric fluid .

Wire EDM is a fantastic CNC machining method for intricate and precise metal cutting. We explain how it works, how you can use it, and more. Electrical Discharge Machining, also referred to as spark machining, is an alternative to traditional machining that uses thermal rather than mechanical forces to remove material. Specifically, a hot electrical spark is what removes material from the workpiece. As the name implies, electrical discharge machining or EDM machining uses electrical discharges to shape metal parts. The process, which we’ll dive into in further detail below, is characterized by its high precision and the ability to easily machine hard materials like hardened steel or carbide. Electric discharge machining, also known as spark erosion, electro-erosion or spark machining, is a process of metal removal based on the principle of erosion of metals by an interrupted electric spark discharge between the electrode tool cathode and the working anode.

Electrical Discharge Machining (EDM) is a manufacturing technique that removes material from a workpiece through a series of rapid electrical discharges between electrodes submerged in a dielectric fluid.

A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts. For example, a stamping die can be machined with 1/4 degree taper or a mold with one degree taper in some areas and two degrees in another with precision. Non-contact precision machining of complex shapes with excellent surface finish. (Image courtesy of Makino.) Electrical discharge machining (EDM) has long been the answer for high accuracy, demanding machining applications where conventional metal removal is .Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges.

wire electrical discharge machining process

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1]Electrical Discharge Machining (EDM) is a precision manufacturing process utilizing controlled electrical sparks to remove material from conductive workpieces. The process operates through electrical discharges between an electrode and workpiece, both submerged in a dielectric fluid .

Wire EDM is a fantastic CNC machining method for intricate and precise metal cutting. We explain how it works, how you can use it, and more.

Electrical Discharge Machining, also referred to as spark machining, is an alternative to traditional machining that uses thermal rather than mechanical forces to remove material. Specifically, a hot electrical spark is what removes material from the workpiece. As the name implies, electrical discharge machining or EDM machining uses electrical discharges to shape metal parts. The process, which we’ll dive into in further detail below, is characterized by its high precision and the ability to easily machine hard materials like hardened steel or carbide. Electric discharge machining, also known as spark erosion, electro-erosion or spark machining, is a process of metal removal based on the principle of erosion of metals by an interrupted electric spark discharge between the electrode tool cathode and the working anode.

Electrical Discharge Machining (EDM) is a manufacturing technique that removes material from a workpiece through a series of rapid electrical discharges between electrodes submerged in a dielectric fluid.A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts. For example, a stamping die can be machined with 1/4 degree taper or a mold with one degree taper in some areas and two degrees in another with precision. Non-contact precision machining of complex shapes with excellent surface finish. (Image courtesy of Makino.) Electrical discharge machining (EDM) has long been the answer for high accuracy, demanding machining applications where conventional metal removal is .

wire electrical discharge machine

haunted house sparking metal

hawke pl612 junction box

wire cut electrical discharge machining

Zenith Self Tapper Screws are suitable for fixing into thin metal or timber, or joining sheet metal for a low-profile head finish - for example, garden shed construction. 304 grade stainless steel for superior corrosion resistance

cnc electrical discharge machining|wire electrical discharge machining process